Manufacturing Design

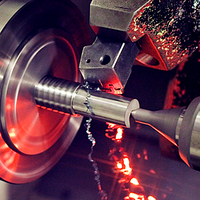

We use only high-class materials with certificate. Our ball screws and nuts are produced from high strengh steel suitable for rolling bearing applications. Spindles and nuts for the RACO ball screws are ground in air-conditioned work shop facilities. We spare no cost or efforts, since the accuracy we guarantee can only be achieved by precision grinding. The geometrically true form of our ball nuts and the spindle profiles are crucial for the considerably longer service life of our ball screws

Beyond this, our inductive hardening technique with its considerable penetration depth creates the prerequisite for each spindle to be re-ground, so that it will be reliably for a long life. This means you benefit with lower costs and shorter downtimes in the event of a breakdown.

Quality Requirements for RACO ball scews

The manufacturing is made upon request based on your drawing or technical info and the manufacturing procedures for each RACO ball screw will be selected individually according to the preferred criteria as outlined below. Each step of manufacturing is inspected for hardness and cracks to assure our defined high quality level which is documented in accordance to the ISO 9001/Rev.2000 regulation.

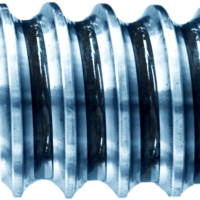

The RACO nut design

The core of a RACO ball screw is the nut with its single lead ball return that has been developed by us. This design has been protected by a universal patent and ensures that the balls are returned within the ball screw nut at the shortest possible route. This gives you the benefit of a higher rated load with the smallest possible nut dimensions, meaning higher efficiency and a longer service life. RACO ball screws with a single or double nut (nut and counter nut) can be preset free from backlash, so that the correct and recurrent positioning can be ensured even if the load or direction change.