RACO quality products in the commercial malt house Avangard Malz

Moderne Elektrozylinder und neues Steuerungskonzept für Siloanlagen

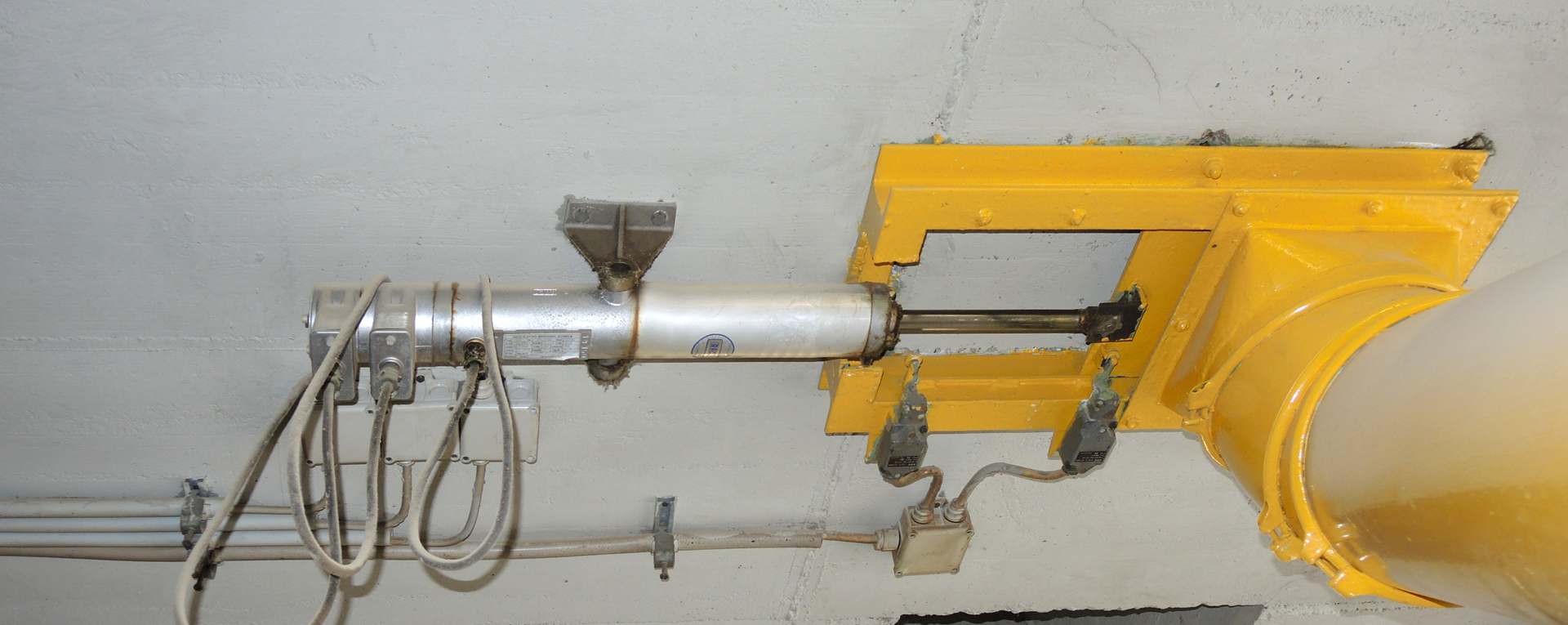

Modern electric actuators and a new control concept for silo systems For more than 30 years Avangard Malz has been using RACO electric actuators as actuation elements on the valves of its silo systems. Modernisation and partial replacement of these components with state-of-the-art products of the next generation started in 2014 and was completed one year later. RACO has also developed and installed a control concept for monitoring and visualising the processes in the silo, allowing the commercial malt house to track and check the processes directly via screens in the control room.

read more...

Malt in precisely the right mixing ratio – thanks to RACO electric actuators

The malting process is complex and requires a high degree of precision in a multi-level process involving cleaning, softening, germination and drying the grain. As soon as the enzymes in the corn have been activated by the germination process, drying is very important. The degree and duration determine the development of the colouring and aromas in the malt that ultimately dictate the taste of the beer. Breweries work with an individual mix of various barley malts. The RACO electric actuators are used during this production step: they act as dosing valves at the outlets of the malt silo. Activated via the central control unit, they control the flow quantity so that the required mix can be provided for every Avangard Malz customer.

Successful project implementation during on-going operations

The concept of the so-called ‘RACO valves’ has proven successful for Avangard Malz for decades. Potentiometers act as position encoders for the TARGET positions, and the display reports the respective ACTUAL position of the valve that is moved by the RACO electric actuator. The idea was to keep this concept, but the control equipment needed to be modernised. For commercial reasons this needed to be accomplished without interruption operations, which is why RACO developed a project plan that spanned a full year. At the end of the day, the actuators in the silo systems were modernised without any downtimes and also inexpensively.

RACO tendered the removal and inspection of the existing drives in several project phases. The company provided a proposal for the overhauling or replacement of components for every charge, which meant that Avangard Malz was able to decide the further course of action on a case-by-case basis. This approach allowed RACO to make lots of costs savings for the malt house. It was also planned to overhaul the existing electric actuators and update their mechatronic systems to the state of the art. RACO also integrated the system into the software of the control system at Avangard Malz and then commissioned the system.

Reliable and safe equipment for higher productivity

The project was completed to the full satisfaction of Avangard Malz in February 2016. The employees at Avangard were particularly impressed with the visualisation of the silo systems on the screens in the control room. The modern control technology is reliable and sustainable. Service head, Elmar Ernst, praised the long service life of the RACO products and is highly impressed by the manufacturer’s electro-mechanical drive solutions: ‘Hydraulic actuators work with oil for force transfer, which means that leaks are a frequent problem. Contamination of our products or systems with hydraulic oil would lead to serious damage.” In contrast, the electric actuators are absolutely safe with minimal susceptibility to faults. “Avangard Malz has positive experience with RACO products for the past 35 years and now we are equipped for the next few decades,” says Ernst.

Avangard Malz is one of the largest malt house groups in Germany. Founded in 2006, the company now has four domestic sites and produces for breweries in Germany, Europe and overseas. (http://avangard-malz.de/)