RACO - leadscrews

Depending on the conditions of the application and the adjustment task, ball screws or trapezoidal screw drives can be used:

| Ball screw drive | Trapezoidal screw drives | |

|---|---|---|

| Duty cycle > 50% | ✔ | x |

| Adjustment speed > 50 mm/s | ✔ | conditionally suitable |

| hard shocks | x | conditionally suitable |

| Efficiency | > 85% | < 40% |

| Positioning accuracy | ± 0,05 mm | ± 0,3 mm |

| Operating temperature | -20 bis +70 °C | -20 bis +70 °C |

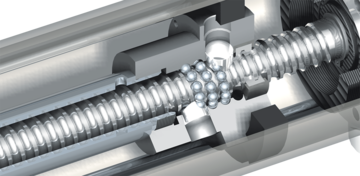

Ball screw drive

The ball screw drive is a ground spindle made of high-strength steel and has no self-locking due to the very personal friction of the rolling contact between the balls and raceways. The installed drive power is dealt with in force complaints. This type of spindle is ideal for applications that require a different degree of precision in terms of positioning and repeat accuracy.

When you should choose a ball screw drive:

- high adjustment speed

- high duty cycle

- high required repeatability

- highly dynamic application

- high efficiency

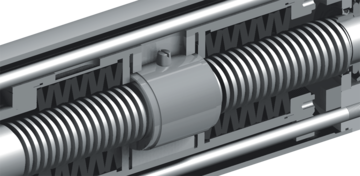

Trapezoidal screw drives

Thread whirling

We produce trapezoidal screws using the so-called whirling process, a metal-cutting process in which a tool gyroscope rotates around the raw material rod. In the process, the gyroscope is displaced from the centre of the axis and thus cuts a chip from the raw material. If the gyroscope is now provided with an axial feed, a thread is produced.

Advantages of the whirling process:

- The tools are independent of diameter, profile and pitch.

- Low tool costs

- Cost-effective for small batch sizes

Thread grinding

Grinding is used for precision trapezoidal screws, which are manufactured in hardened versions. Thread grinding is a metal-cutting manufacturing process for the exact machining of a defined profile geometry in hardened material. Due to the comparatively long machining times, depending on the number of grinding passes, this process is cost-intensive.

For the following specifications, however, the effort is worthwhile:

- for multi-start threads and special profiles

- for spindles with thread lengths of 1m and more

- for large thread profiles (delta between outer and core diameter >20mm)

- for the production of spindles for hydrostatic screw drives