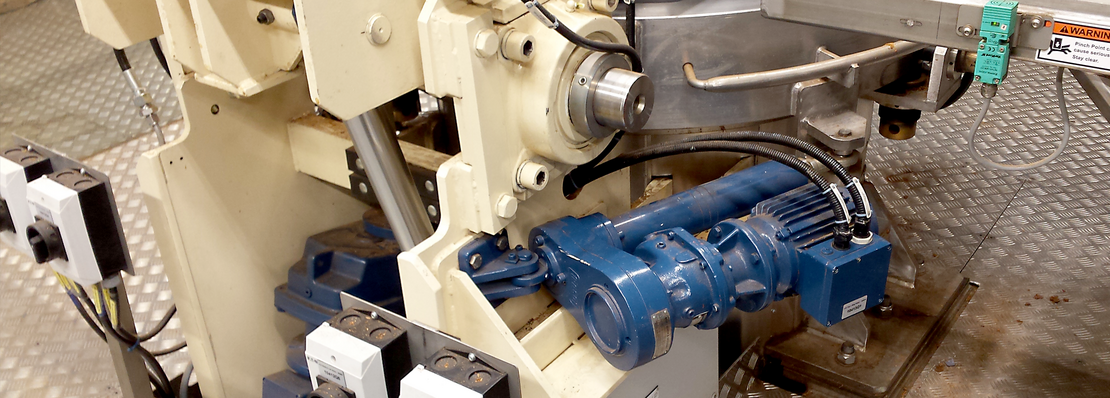

RACO electric actautors for the actuation of container lids in the tobacco industry

By means of an electric cylinder, the lid of the pressure vessel is positioned in the open and closed position via a hinge. Due to the kinematics, the forces via the lever arm change to a maximum when closing in the horizontal position.

- At the same time, this so-called closed position must be approached very precisely at creep speed to the sealing surface in order to be able to turn the pressure vessel's locking ring easily.

- The swivelling process over 95° should take place in max. 15 seconds.

- A force limitation, e.g. in case of obstacles, should stop the drive.

The RACO solution: The electric cylinder is equipped with RACOmatic® and is available for the connection variant "two adjustable end positions" is parameterized. In this way, the motion profile can be optimally adapted to the resulting force of the "load arm" and a minimum operating time for the process can be achieved. The electric cylinder moves slowly at creep speed to the closing position until the current consumption reaches the preset limit value and the current position value is stored. The current consumption monitoring enables an emergency shutdown in case of overload. To open the pressure vessel, the electric cylinder moves directly with increased frequency correspondingly fast from the "closed" position to the "open" position.