Bulk material technology - Actuating devices in the field of material transport

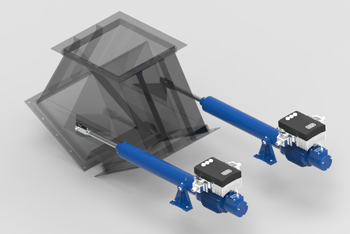

In the field of material transport of bulk materials, RACO electric actuators are used for a wide variety of tasks. Starting with the intake of bulk material, e.g. by bucket wheel excavators, during transport via conveyor belts, in distribution via diverter gates (chutes) and material flow dividers, up to loading onto wagons or ships or storage in silos, bunkers or stockpiles.

Process improvement through automation

In bulk solids technology, the trend towards automation has steadily increased. With the RACOmatic®, RACO offers the ideal solution for integrating electric actuators into a higher-level control system or/and for fulfilling a corresponding requirement profile for the process as a decentralised actuator. With RACO electric actuators you can automate your processes effectively and economically by optimally adapting travel profiles with acceleration and braking ramps as well as setting speeds that can be adjusted along the stroke matched to the application. This is also possible on site with the RACOmatic® Software Tool. Such automated processes minimise the wear of all components as the movements take place within the specified limit values. At the same time the energy requirement is low, which increases the economic efficiency of the production processes in your plants.

read more...

Features of the RACO Electric Actuator:

- High efficiency of the mechanics results in a high power density.

- Low electrical drive power and low energy consumption during stand still guarantees economic efficiency.

- Environmentally friendly and safe operation, as there are no losses due to leakage or freezing problems like in systems with auxiliary media.

- Simple, cost-effective installation and commissioning, as only the electrical connection has to be made.

- Various equipment options to protect or meet customer requirements.

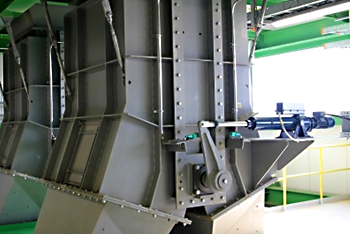

The robust module system is particularly suitable for the toughest operating conditions in combination with high positioning accuracy. Many thousands of RACO electric actuators have proven to be highly precise and reliable under extreme operating conditions such as heat, cold, dust, humidity and vibrations.

Applications for RACO Electric Actuators:

- Reclaimer wheel adjustment, bucket adjustment on the reclaimer wheel, boom extension on the scraper, etc.

- Chutes, diverter gates, pendulum flaps, bulk material flow dividers, trickle material flaps, etc.

- Belt ploughs, belt edge controls, conveyor belt adjustments, conveyor belt tensioners, baffle plate adjustments, etc.

- Clamshell gates, slinger belt adjustments, dosing slide, etc.

Please call us at the following telephone number: +49 2336 4009 40 or send us an e-mail to sales@raco.de with a filled in questionnaire (Fragebogen verlinken). Further information regarding the application like sketches, drawings, specifications, etc. will be highly appreciated. We would be pleased to submit you an offer for the optimal RACO electric actuator for your application. You can rely on our more than 65 years of experience in the field of bulk solids technology.

PS: Our RACO electric actuators of the high performance series are also available with ATEX certification!