Shearing equipment for aerated concrete

4 RACO Elektrozylinder with RACOmatic® in synchronized operation mode

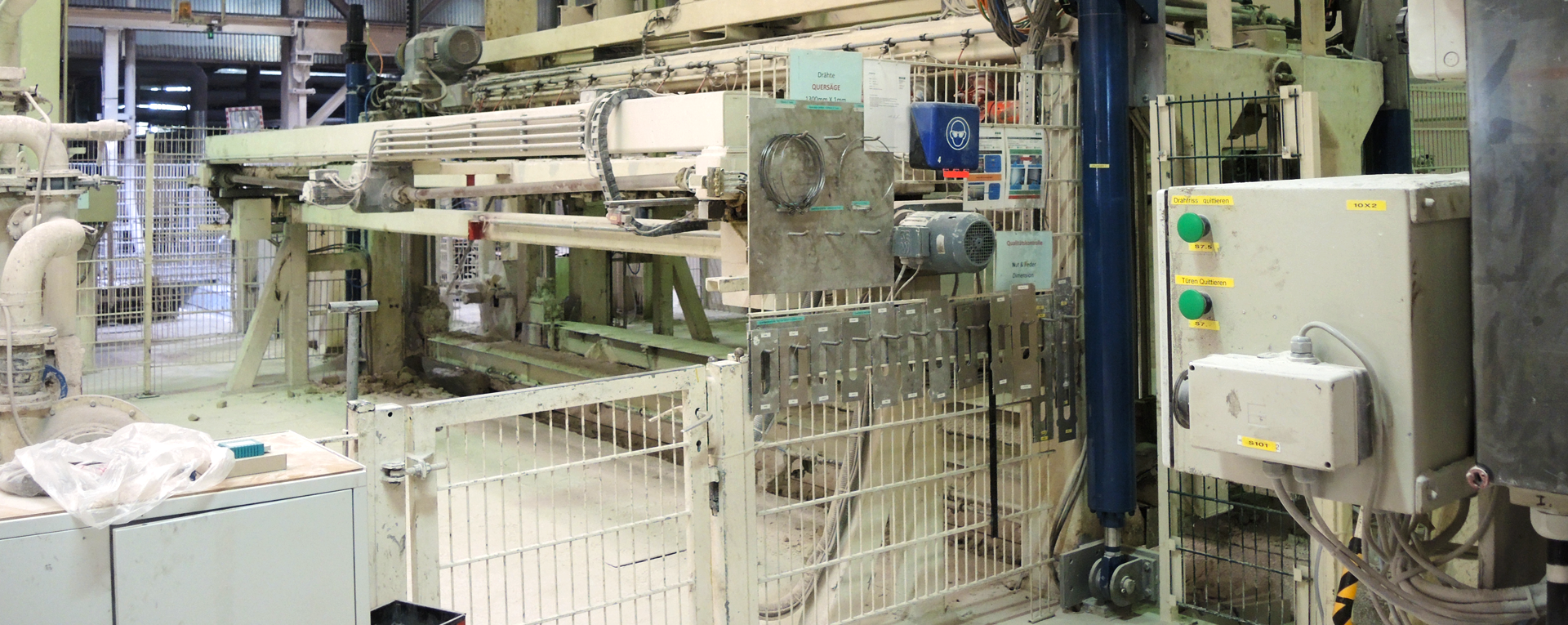

During the production of aerated concrete the raw mixture is poured into blocks. These

blocks run through a shearing system before curing and are cut in longitudinal and transverse direction. While being cut in longitudinal direction the block will pass through wires which cut the material during the travel.

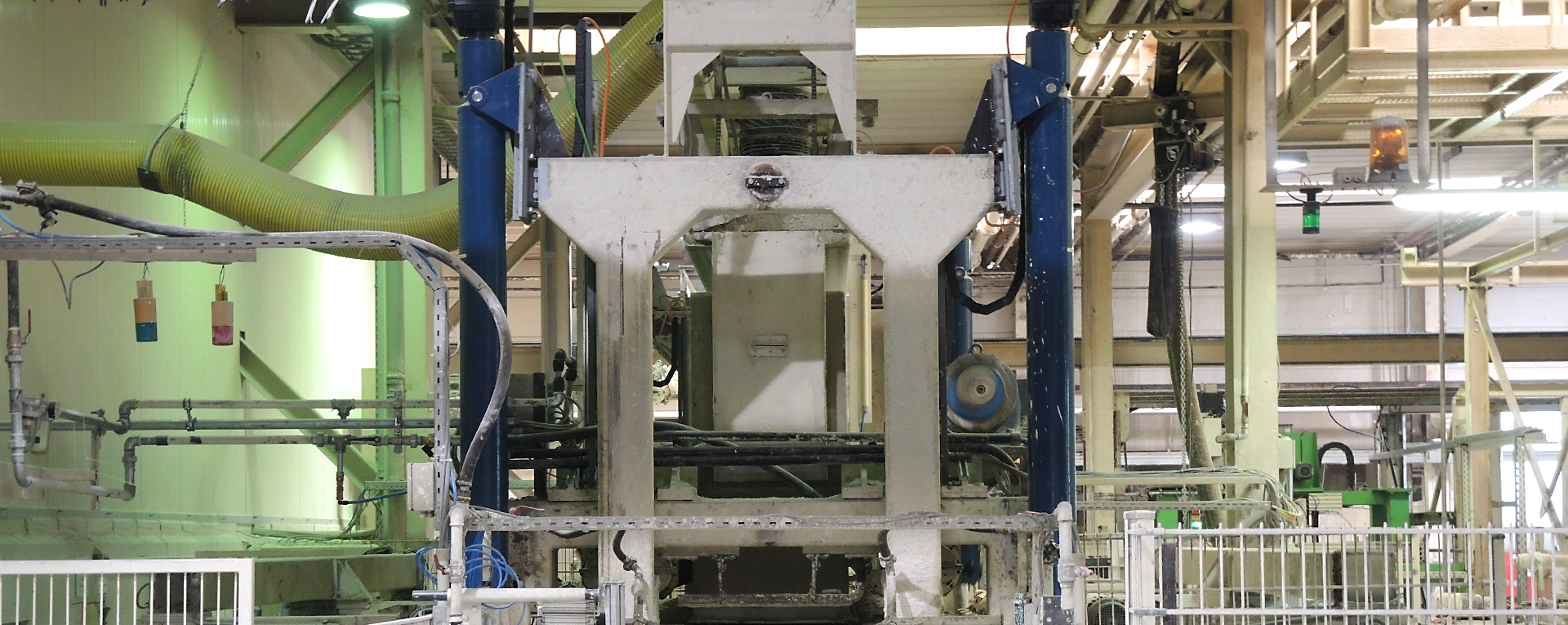

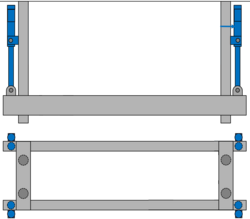

A cutting in transverse direction during the travel is not possible – for this reason a frame with the wires will be lowered and lifted by 4 actuators.

For a straight cut it is important that the frame is lowered consistently. During the lifting the wire has to be raised through the just made cutting gap exactly.

The precise activation and control for the synchronization is extremely relevant for the process quality in order to avoid waste during the production.

With four RACOmatic® actuators a synchronous control was implemented which affords the user a precise activation and control and ensures furthermore a high synchronization precision.

Customer´s benefit:

- Exact synchronization by Master-Slave-Principal

- Increase of product quality effected by exact cutting results

- Higher productivity by troublefree continuous operation

- Increase of process quality by reduction of waste

- Reduction of costs by higher endurance of the RACO electric actuators

- Reduction of costs by less maintenance effort