Trapezoidal Screws (ACME) and Nuts

RACO ACME screws consist of a whirled or optionally ground spindle in combination with a spindle nut made of special bronze. Depending on the choice of spindle geometry and the drive, self-locking at standstill is achieved for this design. We manufacture your customized ACME threaded spindle, multi-start ACME threaded spindle, and threaded nuts according to a drawing. RACO also manufactures so-called hydrostatic spindles.

Thanks to our innovative and high-quality manufacturing process, we realize flank surfaces that are ideal for the adhesion of lubricants. The surface quality prevents the "slip-stick effect,” which describes the jerky sliding of solid bodies moving against each other. As a result, our ACME threads have a longer service life.

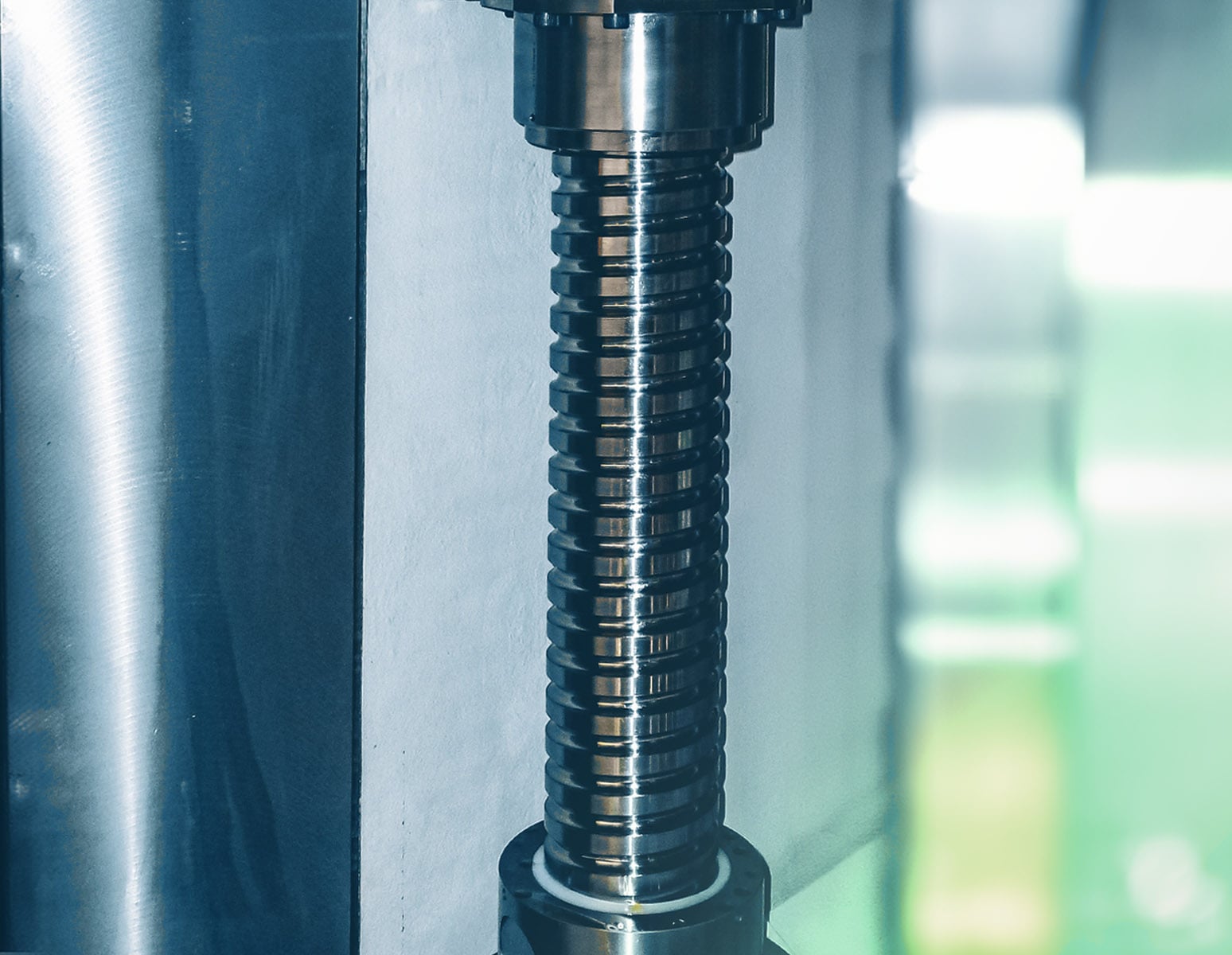

Grinding in a temperature controlled room requires compliance with tolerances for holding the workpieces in the machine, as well as their dimensional accuracy in terms of radial and axial run-out. The pitch distortion caused by heat input (whirling and hardening) is corrected during grinding and thus eliminated.

ACME (Trapezoidal) Threaded Spindles According to Your Specifications

In addition to standard ACME threads - with the corresponding ACME thread nuts - we also manufacture special threads for you that deviate from common standards and norms.

We would also be happy to supply ready-to-install lead screws or ACME screws including threaded nuts, turning and milling work, heat treatment, and surface treatment.

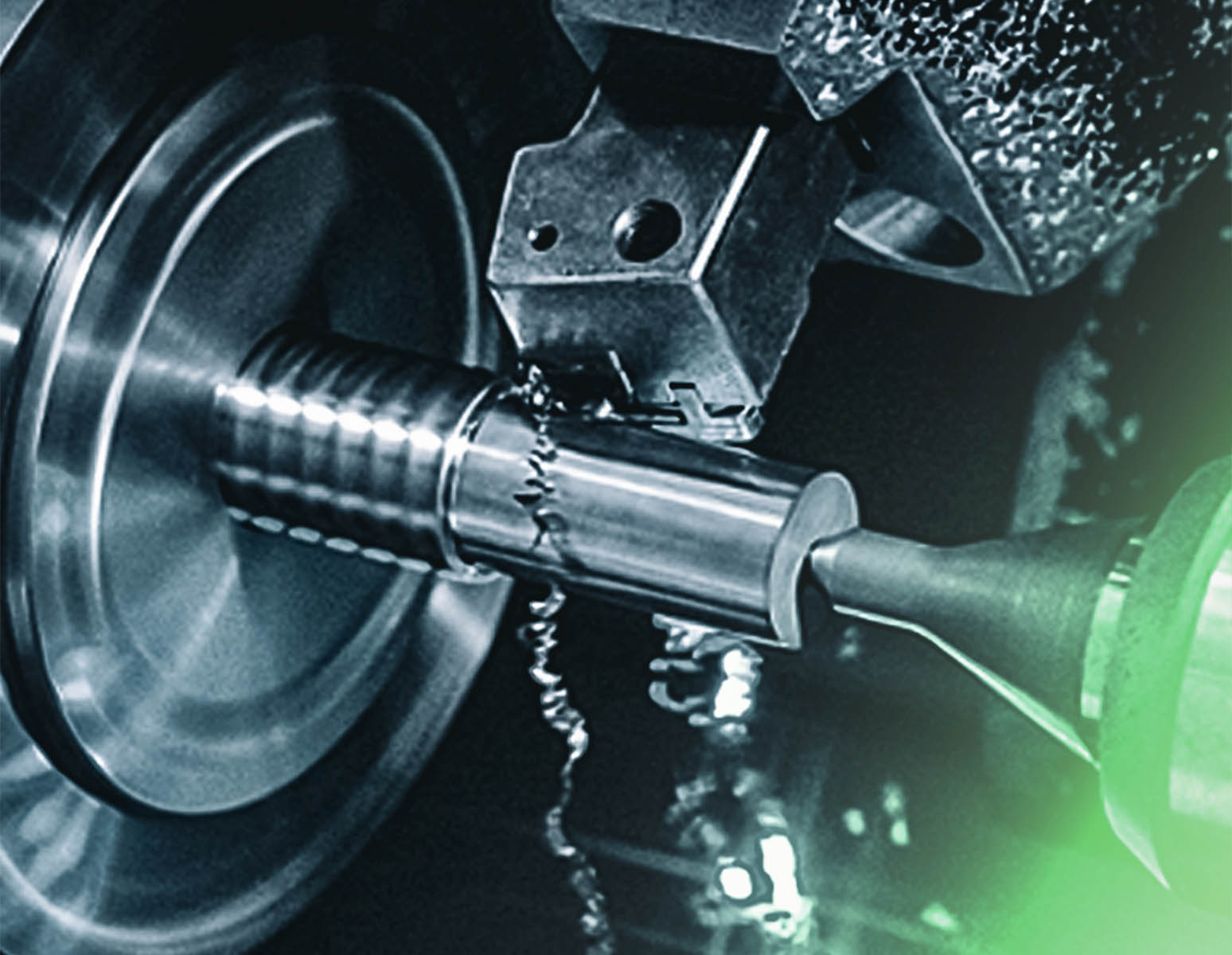

The Whirling Process

We produce ACME screw drives using the so-called whirling process, a metal-cutting process in which a tool gyroscope rotates around the raw material bar. The gyroscope is displaced from the center of the axis and thus cuts a chip from the raw material. If the gyroscope is then provided with an axial feed, a thread is created.

Advantages of the whirling process

-

The tools are independent of diameter, profile, and pitch

-

Cost-effective for small batch sizes

Thread Grinding

Grinding is used for precision ACME screws that are manufactured in a hardened version. Thread grinding is a machining process for the exact machining of a defined profile geometry in hardened material. Despite the comparatively long machining times and higher costs (depending on the number of grinding passes), this process is still worthwhile for:

-

multi-start threads and special profiles

-

spindles with thread lengths from 1 m (39.4 in)

-

large thread profiles (delta between outer and core diameter >20 mm (0.79 in)

-

the manufacturing of spindles for hydrostatic screw drives