DURABLE, HIGH-PRECISION BALL SCREWS

RACO has been developing and manufacturing precision ball screws for more than six decades and is one of the leading manufacturers in Germany in terms of technology and quality. Together with our valued customers, we develop customized ball screws whose profile geometry is perfectly adapted to the load spectrum and the available installation space.

RACO manufactures ball screws for:

- Machine tools (on request and according to your specification)

- Measuring and testing equipment

- Special applications for simulations in research and development

In machine tools, RACO ball screws guarantee the highest standards of positioning accuracy for reproducible results and a long service life thanks to their profile and surface quality.

PRECISION BALL SCREWS FOR DEMANDING APPLICATIONS

We work together with our customers to develop customized ball screws whose profile geometry is perfectly adapted to the load spectrum and the available installation space.

RACO ball screws features:

- Fast actuating speed

- High duty cycle

- Best repeat accuracy

- Dynamic applications

- High efficiency

- Very efficient

We see ourselves as a development partner and manufacture with the highest precision using patented technologies.

We look forward to evaluating your application.

Sales & Consulting Ball Screws

Mr Dipl.-Ing. Holger Herzer

Phone +49 2336 400 9-40

RACO Ball Screw features

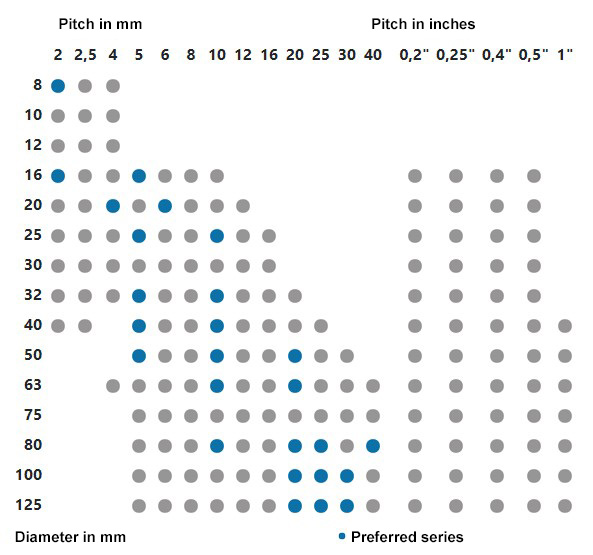

RACO offers high-precision ball screws from 8 mm (0.314 in) to 125 mm (4.92 in) diameter, with a total length of up to 8 meters (315 inches) special profiles on request.

The following are some criteria you can select from:

- Load (static and dynamic)

- Maximum speed (critical speed)

- Buckling strength (optimum rigidity)

- Accuracy class (permissible pitch deviation)

- Backlash (if necessary, preload of the spindle nut)

- Axial play (pre-tensioning of the spindle nut if necessary)

- Service life according to the specified operating conditions

- Environmental influences of the application

- Lifecycle costs

We develop customized ball screws with perfectly adapted profile geometry for the required load spectrum.

Do you have special requirements? Then get in touch with us.

OLD SYSTEM, NEW DRIVE. RETROFIT OF BALL SCREW DRIVES IN OEM QUALITY

In the event of a catastrophic failure of a screw drive, RACO offers a fast repair and reproduction service for many machines from well-known manufacturers.

Get in touch with one of our experts. We will advise you on the next steps.

More than 6 decades of experience

Large variety of manufacturers

Help as quickly as possible

Our promise: we keep your downtime to a minimum.

RACO manufactures new actuators and facilitates repairs at our Bethel Park location which allows for maximum vertical integration. Thanks to decades of experience and the modular RACO system, we can provide both repairs and replacements quickly. We will do everything possible to minimize downtimes and breakdowns of systems and machines.

RACO can replace ball screws from other manufacturers:

- Droop + Rein

- DIAG

- Cover

- Waldrich

- Hessap

- Heyligenstaedt

- Reishauer

- Reckermann

- Forst

- Lindner

Patented Technology

The single overruns, the ball groove profile, the preloaded single nut and the short-stroke ball screw are patented by RACO.

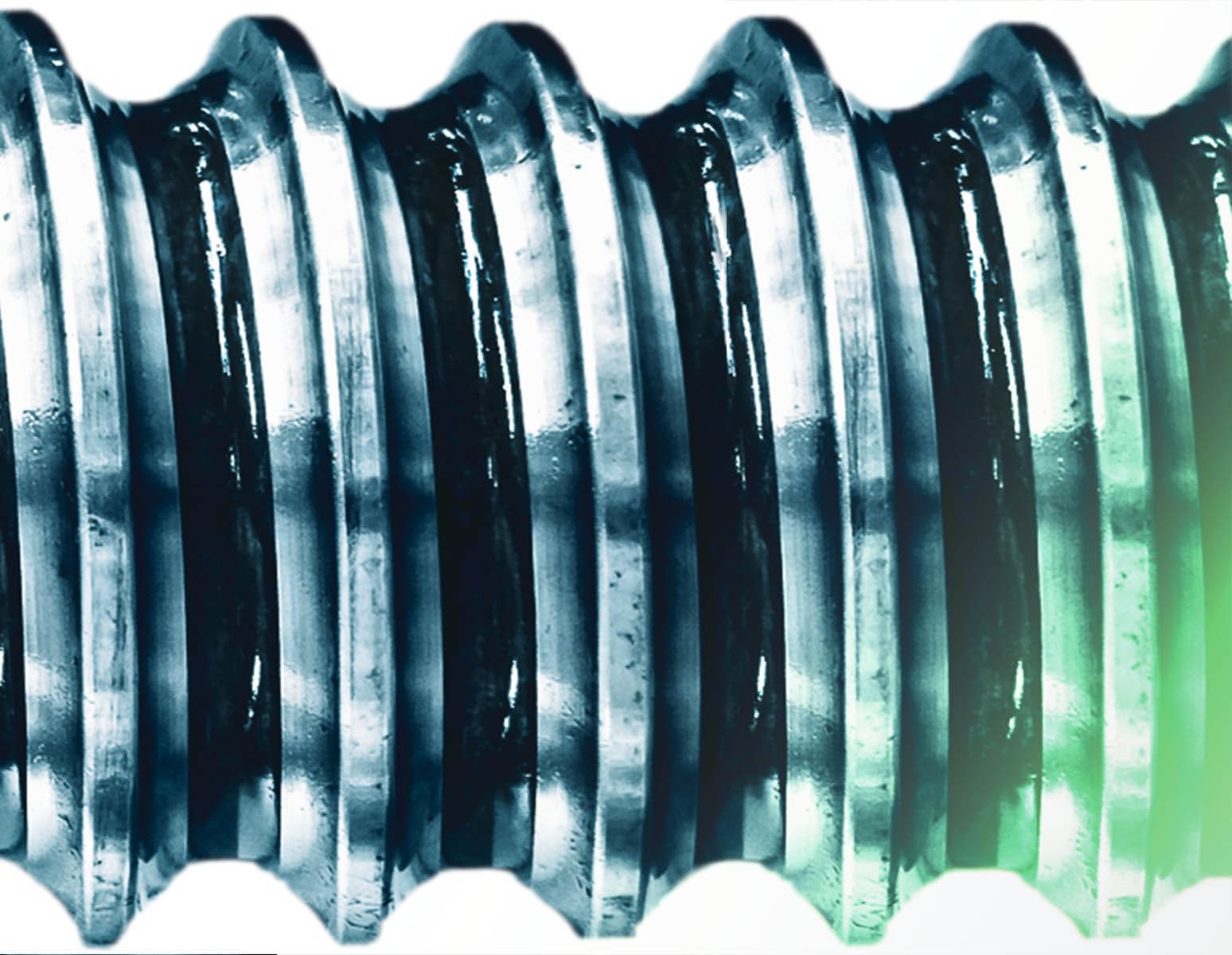

Highest-precision production using a grinding process

We exclusively use various grinding processes in a temperature controlled environment as our manufacturing standard. Grinding is not only the best-known process in the industry, it also produces by far the best results in terms of the performance characteristics of ball screws. However, grinding high-precision threads is time-consuming and requires a series of preparatory operations. RACO masters these challenging operations and assembles the components in the final assembly with the utmost care. The precision of the thread has a particular influence on the dynamic behavior of the ball screw drive. The RACO ball screws are highly precise and have a high degree of efficiency thanks to their optimized design.

Induction Hardening

RACO ball screw spindles are induction hardened. The applied hardening depth of the ball raceway allows regrinding to the next larger ball diameter the event of wear or damage caused by overload or collision. This means the ball screw drive does not necessarily have to be completely replaced. Another aspect is the special profile geometry combined with the option of selecting the ball diameter and number of balls according to the required rigidity. RACO continuously monitors exact compliance with the profile geometry during production.

Each individual production step is monitored, particularly with regard to the degree of hardness and crack formation, in order to guarantee our high quality standard and is documented in accordance with ISO 9001/Rev.2000.

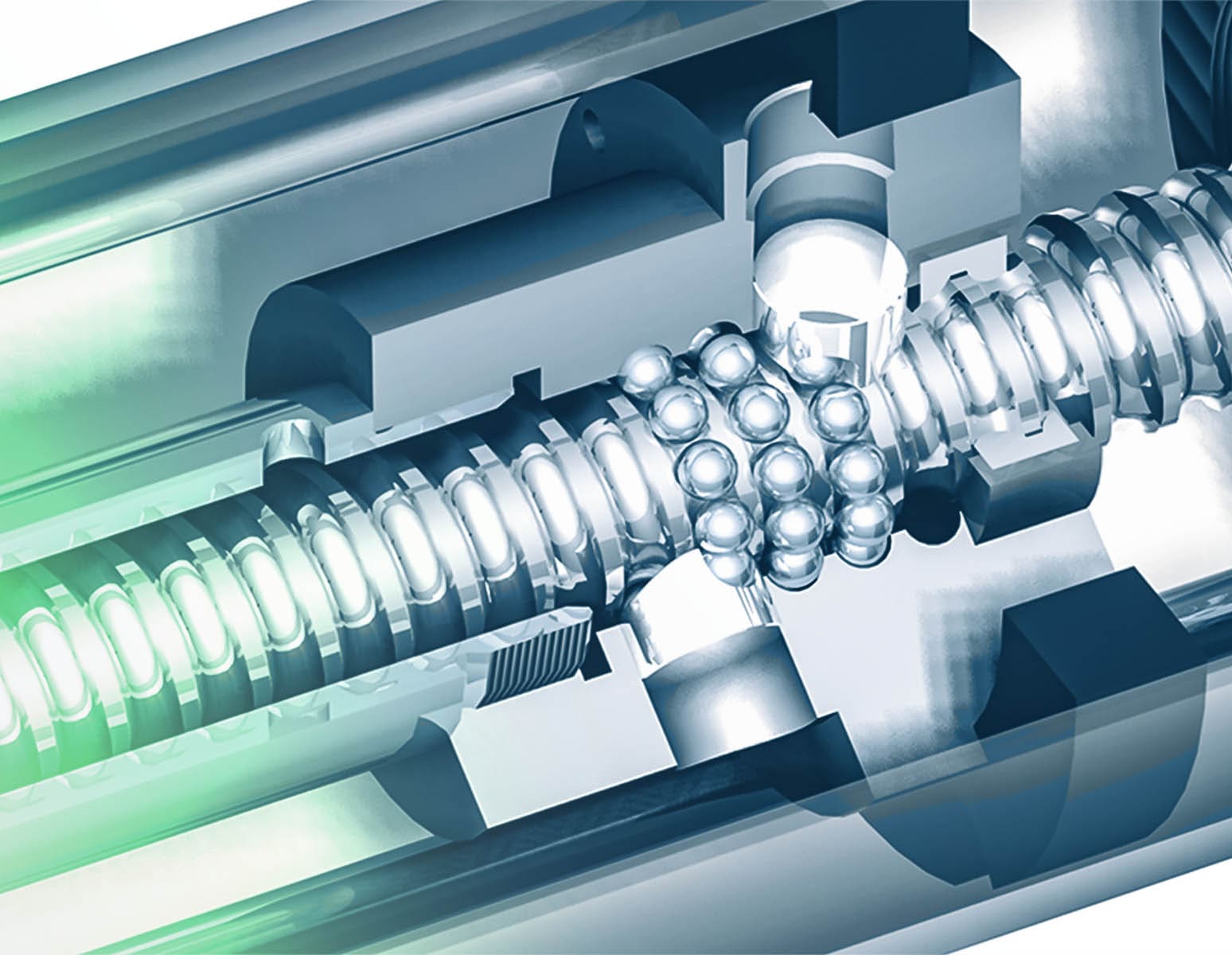

The Spindle Nut Design

RACO's patented ball deflection technology allows a return of the balls into the load-bearing thread in the shortest possible way. High loads can thus be withstood despite the short and compact design and enable efficient use with a long service life. The backlash is neutralized by a preload when using single and/or double nuts, thus achieving exact positioning even with repeated actuation, even if the load direction changes.