Motor drives for RACO actuators

When selecting the motor or motor power for an electric cylinder, the right combination with the respective screw drive is important for a balance of forces of the moving masses. With its experience as a motor manufacturer specifically for electric actuators, RACO meets these requirements comprehensively with the latest generation of motors. In combination with spur gearboxes or bevel and worm gearbox stages, parallel shaft gearboxes, belt and planetary gearboxes, optimum torque and speed adjustment is achieved. Holding brakes and centrifugal brakes complete the system according to the individual application.

RACO three-phase AC motors with a low moment of inertia are suitable for inching operation and for accelerating large masses. The motor characteristics with reduced tilting torque ensure a long service life for both the motor and the RACO electric actuator. Protection class IP 54, insulation class F is defined as standard for RACO motors, whereby a higher protection class IP65 and also ISO H as well as numerous special voltages are optionally available.

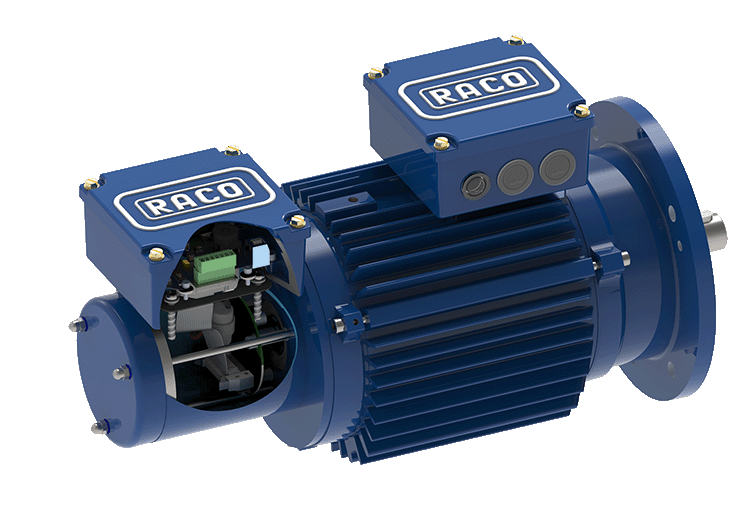

A thermal contact or PTC thermistor sensor is used to protect against thermal overload. The RACO three-phase AC motor has a flange at the 2nd shaft end for mounting additional device housings for sensors such as end position monitoring, position feedback, electronic speed monitoring as an overload protection function or encoder devices.

With the RACOmatic® you receive a “ready to run” control package preconfigured for various operating modes for safe commissioning and reliable operation: a mechatronic drive system.

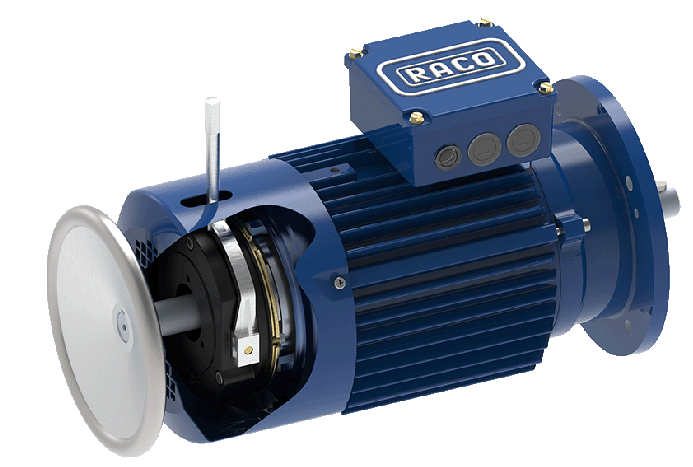

Electromagnetic spring-applied brakes with and without manual handwheel

Electromagnetic brake, version “L” (releasing with voltage)when installing a non-self-locking ball screw drive or multi-start trapezoidal screw drive, but generally recommended for positioning operation and electric actuators with trapezoidal thread in the event of vibrations and shocks, as well as in lifting applications.

Electromagnetic brake, version “B” (braking with voltage = operating current actuated), e.g. for drives that return to a defined position by spring force or external weight force when de-energized. Provide damping so that the cylinder is braked gently or does not run into the mechanical end position. This can be achieved using external damping elements or centrifugal brakes.

Manual adjustment device with accident-proof handwheel without spokes. The versions with a disengageable handwheel have an electric lock.

When combined with the electromagnetic brake version “L”, the brake is designed with a hand release.

For versions with a handwheel, the additional accessory housings are attached to the clutch housing, the belt drive housing or, in the case of larger angular gearboxes with a hollow shaft, directly to the spindle shaft.