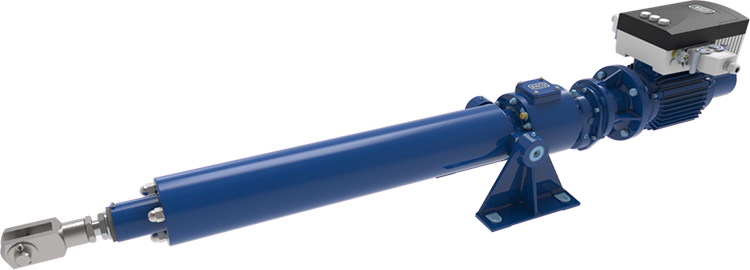

RACO actuators

are subdivided into the following 6 basic assemblies:

- Cylinder (push-pull unit)

- Clutch housing

- Motor with/without gearbox

- Electromagnetic brake

- Manual adjusting device

- Accessories

The actuator mechanical push-pull unit consists of a spindle & spindle nut system for converting the rotary movement of the motor into the cylinder push-pull movement. The spindle nut system is secured against rotation and connected to the extending and retracting push tube. The force is transmitted via the spindle bearing in the bearing housing via the pivot pins / bearing feet / front flange into the on-site construction

The guide cap supports the extension tube and the free spindle end in this area by means of a sliding piece. The long axial guide and the integrated sealing systems ensure optimum efficiency and prevent the ingress of dirt, dust and moisture. Dirt and ice wipers are optionally available for the Type 1 electric actuators, which protect the lip seals from sticking to the protective tube.

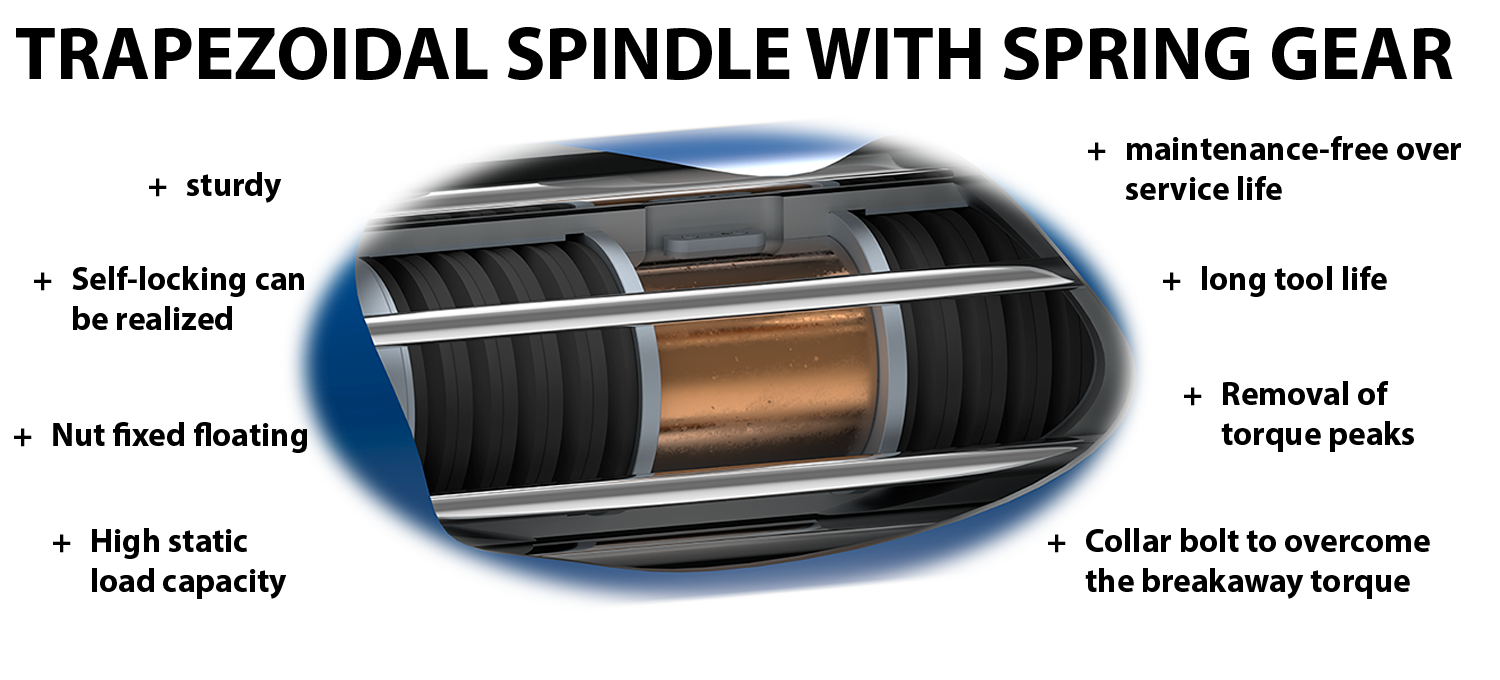

RACO manufactures its own trapezoidal and ball screws, whirled and ground. This means that the screw geometry, profile, ball diameter and pitch can also be adapted for special requirements, for example for higher load ratings or lower load backlash. The choice of materials and high surface quality and hardening depth guarantee a long service life.

Trapezoidal screw drives consist of a whirled or optionally ground spindle in combination with a spindle nut made of bronze. The cost-effective and robust design opens up a wide range of applications. Static loads, which can be many times higher than the nominal adjustment force, are held securely in any intermediate position, regardless of the position. In order to increase the adjustment speeds, multi-start trapezoidal spindles and/or larger spindle pitches are used.

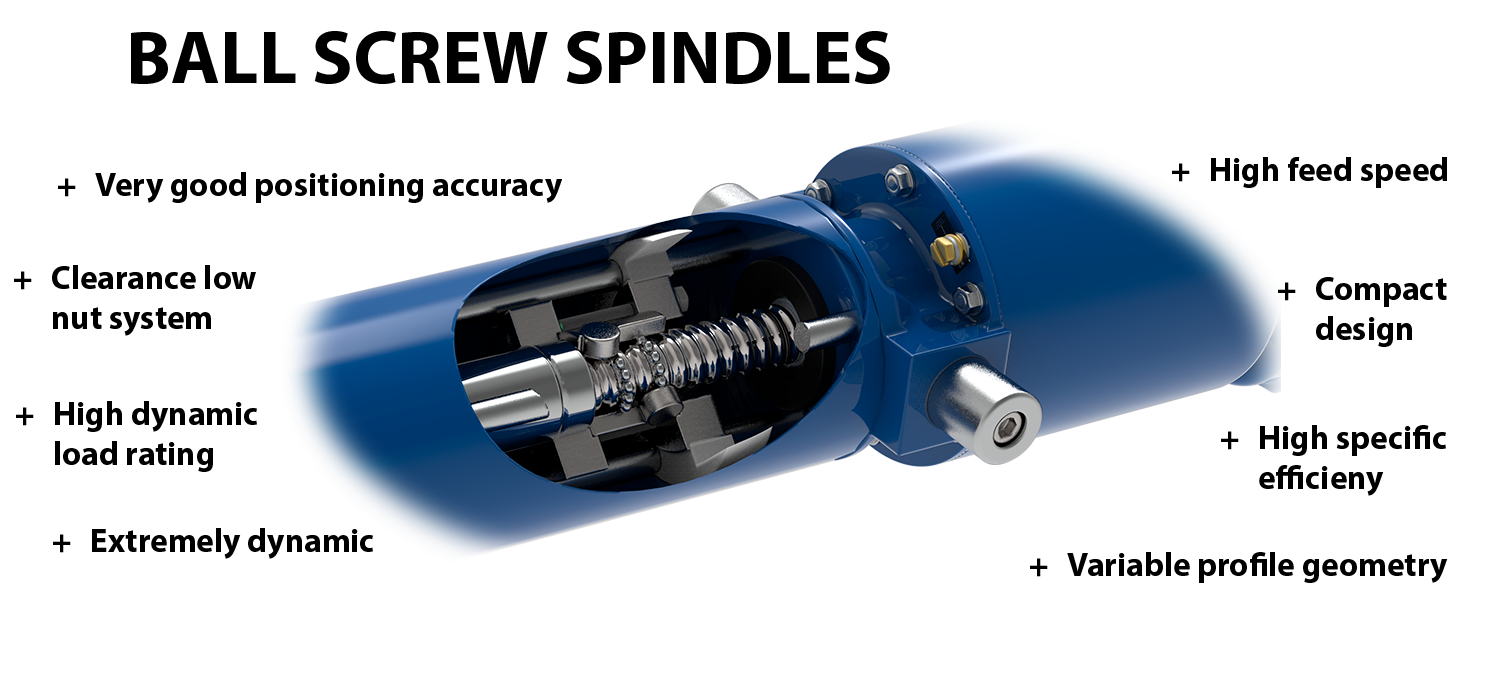

Ball screw drives (KGT) are not self-locking due to their design, as the rolling contact between the balls and raceways between the nut and spindle results in very little friction. Due to the high level of efficiency, the installed drive power can be converted more effectively into actuating force. There is less wear than in a trapezoidal screw drive, which leads to a longer service life of the ball screw drive under the same operating conditions. The individual overruns and optimized crossover pieces for the balls provide additional safety, as other load-bearing threads are still engaged if a ball track is defective. This spindle type is particularly suitable for applications that require a high degree of precision for positioning and repeat accuracy or a higher adjustment speed. Self-locking is realized by brakes adapted on the motor.